The second processing station of 3-Station Thermoforming Moulds (FCS), and the third processing station of 4-Station Thermoforming Moulds (FPCS) is Cutting Station.

|

Top Part of |

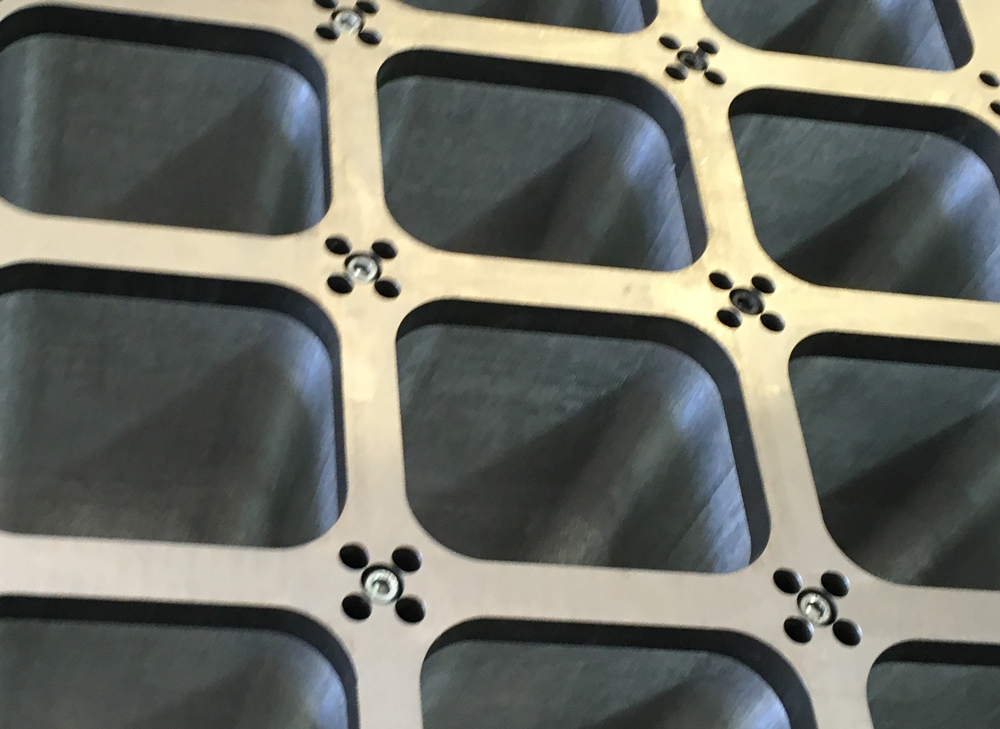

Bottom Part of Cutting Station of a Thermoforming Mould Counter Cutting / Anvil Plate |

|

|

- The cutters can move on two sides.before the cutting station closes, and cutters get in to contact with the sheet, integrated centering pins on cutter templates do align the cutter with the aid of reference centering points on the sheet surface; thus a perfect precision cutting of the product is achieved.

- Cutters used in thermoforming process are manufactured from the most known brands' proven models that the thermoforming market knows well with their quality, and long lasting service life.

- A hard surface that will provide perfect cutting for a very long time is obtained by passing the cutter counter part / anvil plate through a precise heat treatment process. If the product permits, both surfaces of anvil plate is made simetrical, thus the cutting station's service life of the thermoforming mould is almost doubled before the time comes for a regenerative grinding.

- Cutter template installation on the cutting station is made so simple that eliminates the necessity of qualified technician during changing dull cutters. Without loosing time for the change process, one changes the cutter just by uninstalling the dull one through two fixing bolt, and installing back the new one through fixing the same two bolts, that's it, and continue to run! No need to stop the machine for uninstatlling the cutting station out of the machine for cutter renewals anymore!